Crash tests of vehicles are a sure way of determining how safe they and the technologies they pack are in case of unwanted road events. These procedures not only help carmakers determine where and how much to improve a car, but over the years have become in most places on this Earth a mandatory step for rating a new vehicle.

Once the spread of motorized vehicles became unstoppable at the start of last century, carmakers and lawmakers started noticing exactly how dangerous they can be if improperly built or handled. So they started looking at ways to study the effects of impacts on both cars and the people inside.

Historically, it was General Motors who performed the first such test in 1934, when one of its vehicles was intentionally sent into a barrier to see what would happen. Since that time the procedure has evolved to become one of the pillars of carmaking.

In our day and age crash tests are used to determine both the effectiveness of safety systems and the effects various impacts can have on those involved. It’s a fairly cemented and effective process that would have you believe there’s not much one could do to improve it.

You’d be wrong, as Mercedes-Benz showed us all last week, when it announced it conducted the world’s first X-ray crash with a real car.

To properly assess the effects of impacts and the measures to be taken, carmakers record their crash tests with a variety of cameras and sensors. To date, however, no one has managed to use an X-ray camera to see what happens during a crash.

The German carmaker partnered with Fraunhofer-Institute for High-Speed Dynamics’ Ernst Mach Institute (EMI) in Freiburg for this technology demonstration. A C-Class saloon became the star of the procedure, but not the standard one – this C-Class was placed under a linear accelerator that acted as an X-ray camera.

The test is the culmination of several years of hard work between the two partners. Installed in a frame above the roof of the car (and backed by a flat deflector installed under the C-Class), the device uses a one kHz technology as the radiation source, far more powerful than what was used until now during tests conducted behind closed doors.

How powerful? Well, if you want to split hairs, the photon energy of the tool is up to nine megaelectron volts, according to the carmaker. That may not mean much for the uninitiated, but it basically means all the materials inside a vehicle can be screened this way.

The X-ray camera releases pulses that last only microseconds (but can also do that continuously), and it is capable of recording up to 1,000 images per second, 1,000 times more than what standard X-ray machines can deliver.

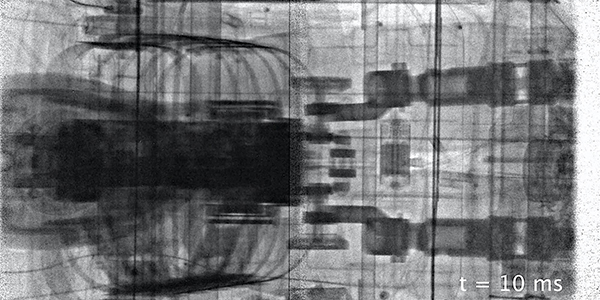

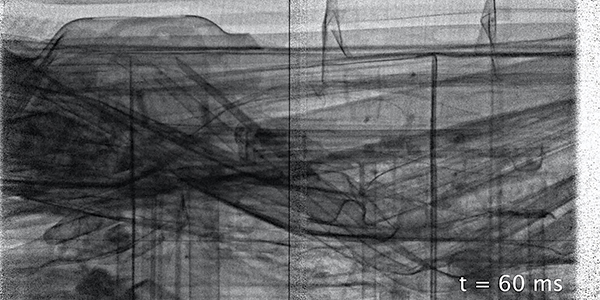

In a nutshell, the camera allowed an intimate view inside both the car’s bodywork and that of the female test dummy that was inside the C-Class during the impact. Such a capability gave Mercedes-Benz the ability to see, for the first time and without motion blur, the deformation processes that take place during an impact inside the materials involved.

But how did this entire test crash go? Mercedes says it opted for a side crash test, with the vehicle hitting a crash barrier at speeds of 60 kph (37 mph). The test dummy was located on the left side of the car, the one that took the brunt of the impact.

During the few milliseconds of the active impact, the X-ray camera recorded about 100 images that were later combined to form a video. The images reveal in new ways what “happens inside safety-relevant components and in the dummy’s body during a crash” – for instance, how the thorax of the dummy is pressed, or how car components are deformed.

For the time being the X-ray crash test technology is only a proof of concept, and we are not told if and when it could become common practice in the development of new vehicles. The system does come with a number of advantages that will probably see it being researched further.

The first one is, of course, the fact that it brings transparency to a level that was unaccessible before, allowing an unhindered view of the internal deformation processes. Then, the high-resolution images obtained this way can be analyzed in greater detail and with precise results.

Last but not least, using an X-ray camera system of this variety does not require complex retrofitting, and it also does not affect the tools already in use for recording various impact parameters.

Work on further developing the system will probably continue, given how Mercedes is one of the most active carmakers when it comes to conducting crash tests – up to 900 of them take place each year at a facility in Sindelfingen, which is almost three per day on average.

Mercedes C-Class World’s First X-Ray Crash Test

21/03/2024

No Comments

Mercedes-Benz | Mercedes-AMG

Click to rate this post

[Total: 1 Average: 5]